With IAA Mobility and the RISC-V Automotive Conference 2025 just around the corner, I’ve pulled together the top themes from recent expert panels that every automotive leader should have on their LiDAR.

By James De Vile, Editor, RISC-V International

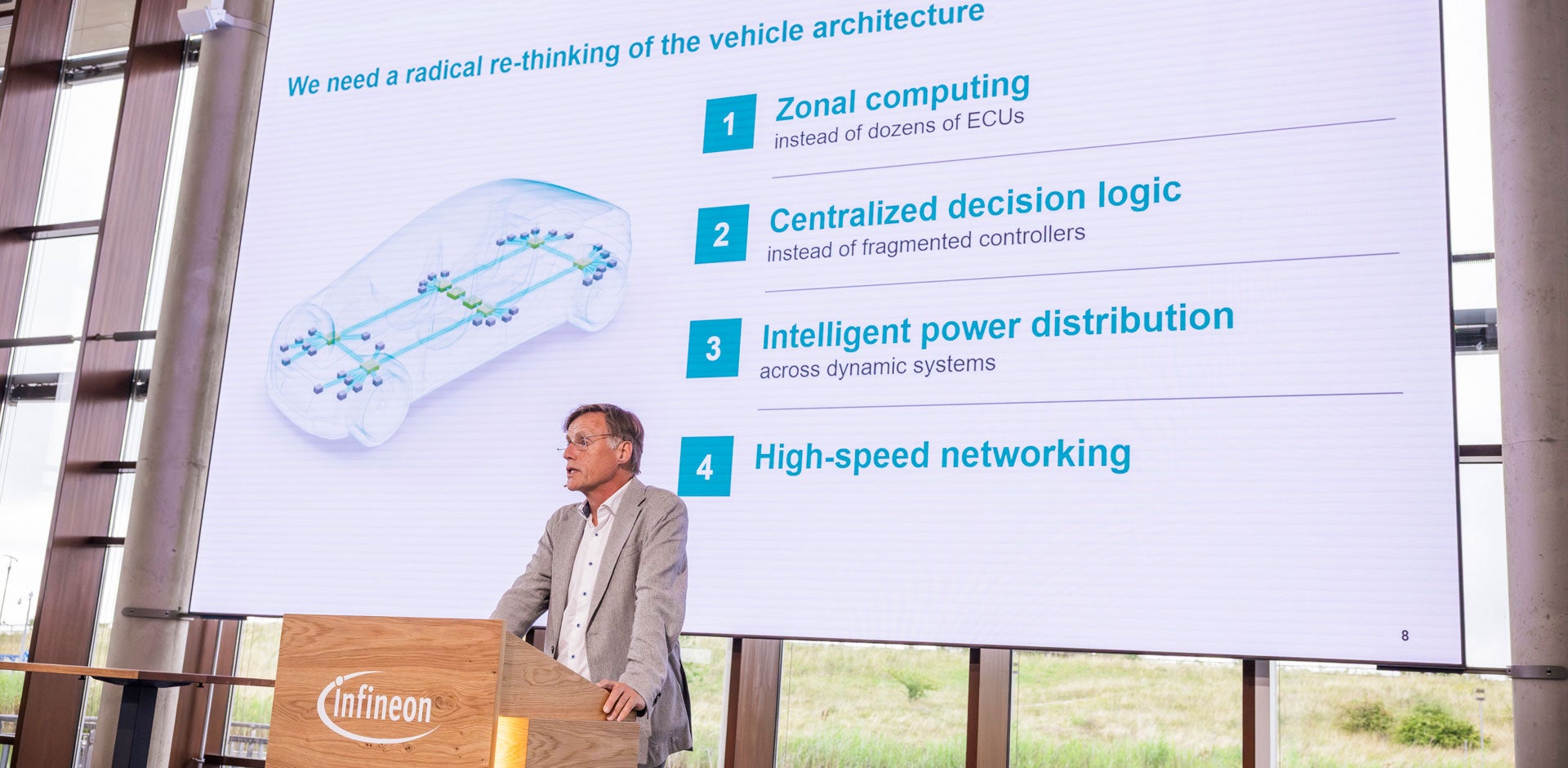

“The car will change in the next five years more than the next fifty years”, said Peter Schiefer, President & CEO of the Automotive division at Infineon Technologies. “Traditional architectures are reaching their limit. That’s why RISC-V will be a game changer, enabling collaboration between hardware and software”, he said, speaking at Infineon’s Automotive RISC-V Ecosystem Summit 2025 in Munich last week.

As the world leader in automotive semiconductor technology, Infineon is far from alone in this belief. Across the global automotive ecosystem, leaders from chipmakers, OEMs, and software specialists are aligned: the car of the future is a software-defined compute platform in motion, and to build it we need to rethink the entire architecture from the ground up.

RISC-V International CEO Andrea Gallo recently partook in several high-profile panels focused on the path to building the car of tomorrow, today. From Munich, to the Automobil Elektronik Kongress (AEK) ‘Computing Architectures of the Future’ session in Ludwigsburg, to Paris for the ‘Accelerating Automotive Innovation with RISC-V’ panel at our own RISC-V Summit Europe, one key theme held steady: We must come together to shape the future of mobility with open standards and strong partnerships.

On September 9th, RISC-V International is hosting the RISC-V Automotive Conference 2025, adjacent to IAA Mobility in Munich. It’s an easy 5-minute walk from the main exhibition, making it simple to attend both events and stay at the heart of the automotive technology conversation.

Ahead of these events, I’ve identified 7 key priorities, shaped by leading voices across recent panels, that outline what it takes to build the car of tomorrow…

1. Zonal Architecture

Infineon CEO, Jochen Hanebeck, speaking in Munich last week

Future vehicles demand flexible platforms that can scale across compute domains and evolve rapidly with emerging technologies and user needs. From entry-level city cars to high-end autonomous fleets, we need compute platforms that support a wide range of performance, safety, and energy requirements.

“We’re moving from distributed software into zonal and central compute”, said Robert Moran, VP & GM, Automotive Processors at NXP, speaking in Ludwigsburg. This approach allows automakers to streamline development, optimize costs, and accelerate deployment by reusing platform components across vehicle lines.

Many modern vehicles on the road today are structured around domain-based architectures, employing domain controllers – dedicated ECUs that handle specific areas like powertrain, infotainment, body control, or ADAS. While effective, domain architectures lead to a proliferation of ECUs and wiring, which increases cost, weight, and system complexity.

In zonal architecture, vehicles are divided into physical zones (e.g., front left, rear right) as opposed to functions within the vehicle. Each is managed by a zonal controller and connected via one or more automotive Ethernet buses. These controllers consolidate the domain-specific functions within their zone, reducing wiring length and cost, improving latency, and simplifying software and hardware integration. Instead of a tangled web of function-specific modules, zonal controllers act as smart hubs in a streamlined, centralized compute environment.

In Paris, Gallo emphasized the scalability of open platforms in supporting this shift: “RISC-V is very appealing in automotive because it scales from ECU to domain controller, to zonal controller, to central compute, within the same base ISA.”

2. Software Ecosystem

You can’t have a software defined vehicle (SDV) without software. And since 2003, the software standard has been AUTOSAR – a global partnership of leading automotive and software companies with support from almost every major OEM and Tier 1 supplier. Last year, Andes, HiRain and HPMicro announced they are working together to build a RISC-V AUTOSAR software ecosystem.

Then there’s Automotive Grade Linux (AGL). While AGL itself is not designed for safety-critical applications out-of-the-box (a car might use AUTOSAR for brake control and AGL for infotainment), community projects and approaches such as the ELISA project and the AGL Functional Safety Task Force are being developed to certify Linux-based systems for safety-critical use cases such as instrument clusters, ADAS, and telematics.

AGL has been ported to the SiFive Unmatched and HiFive Premier P550 boards, and we hope to see an RVA23-compatible AGL release at some point between now and when hardware arrives. But therein lies the rub: given growing competition between carmakers, access to pre-silicon software and tooling is becoming a must-have for automotive system developers. Thankfully, the buzz around RISC-V is lighting a fire under software vendors, who are eager to lead the charge. But, the usual chicken-egg problem arises; to develop ahead of silicon, they need virtual prototypes – like the one Infineon brought forward in March.

Infineon’s Thomas Schneid, speaking in Paris

“Our virtual prototype is designed both to enable the ecosystem and to give early access to leading customers who are eager to explore its capabilities and implications”, said Thomas Schneid (above), Senior Director of Software, Partner and Ecosystem at Infineon, in Paris. “This is an ongoing initiative, so the fidelity of the prototype will continue to improve, and more and more use cases will be supported over time, expanding the ability of different customers and partners to collaborate.”

The entire toolchain, from compilers to operating systems and safety frameworks, must be available and validated well before the silicon reaches customers. This is why upstreaming – contributing RISC-V support for hardware directly into widely used open-source projects like Linux, LLVM, QEMU, and Zephyr – is so vital. It ensures software developers can build, test, and deploy with confidence, without having to reinvent the wheel for each chip.

A strong upstream presence also reduces friction for Tier 1s and OEMs, accelerating adoption and making it easier to maintain support over time – vital in automotive, where platforms must be maintained for a decade or more. That’s where dedicated open source platforms like AGL come in; AGL is designed for the long lifecycles of vehicles, with a focus on extended (10+ year) support and backwards compatibility.

“RISC-V is a great opportunity for us as a car OEM”, said Hartmut Schittko, Head of Semiconductors at Volkswagen’s software group CARIAD, speaking at the last RISC-V Summit in Paris. “We grow closer to the community that does chips and software, because these really need to work flawlessly together, especially when it comes to high performance compute (HPC) tasks.”

3. Open Hardware

The panel at RISC-V Summit Europe 2025

By building around an open, royalty-free instruction set architecture, OEMs gain long-term control and avoid the pitfalls of single-vendor dependency. This is essential for enabling interoperability and accelerating global innovation.

“RISC-V gives us the opportunity to shape an open standard for automotive”, says Schneid. “Infineon was famous for its closed ecosystem, which brought dependability, safety, and quality. But now, by opening up to an open architecture, we’re taking on even greater responsibility: to engage with the ecosystem in a way that ensures this becomes a sustainable model for us and everyone around us.”

One of the biggest advantages of open hardware is that it allows the co-design of optimized hardware and software. OEMs can tailor their RISC-V cores with precision, ensuring they meet specific safety, performance and functional needs within the vehicle.

“Traditionally, we’ve looked to improve accuracy by optimizing the software algorithm, or adding more sensors”, said Maricel Ventura, Senior Principal Engineer at Codasip, in Paris. “RISC-V opens up another dimension: we can optimize and customize the hardware as well. This level of co-design significantly improves things for our software colleagues.”

Building resilience into the supply chain is also far simpler when you start from an open standard, said Schittko. “If done right, you have a common interface layer towards the SDV. It makes it way easier, and with much less investment, to change suppliers if need be – without tossing overboard the entire software stack.”

This, of course, also introduces healthy competition into the supply chain – giving OEMs choice, leverage, and a clear path to mitigate vendor lock-in.

4. Collaboration Through Standards

“Automotive is based on standardization”, said Schneid. “This is the essential foundation needed to ensure the whole system functions properly, achieves scalability, and ultimately delivers efficiency.”

The clearest message echoed by each panel is this: open success requires shared ownership. Everyone must collaborate to contribute real competence and expertise, and in return, the ecosystem must deliver sustainable, equitable outcomes for all involved.

Standards are the catalyst for that collaboration. Without unified standards, the ecosystem fragments, and development slows. Shared specifications and interfaces reduce complexity and unlock ecosystem-wide compatibility. Tackling the future of automotive innovation demands cross-industry collaboration to shape shared solutions, standards, and validation frameworks. Central to that is an open, standardized compute architecture.

“At the CPU architecture level, we are aligning and avoiding unnecessary fragmentation by adopting the concept of profiles”, said Gallo. “Our new RVA23 profile defines a set of mandatory extensions to be included in that core, such as vector, bit manipulation and hypervisor. It gives developers a clearly defined hardware target. The goal is to ensure consistency and software portability across the ecosystem.”

“Having a unified standard working under the hood reduces a lot of the liabilities and the implications of a potential lock-in”, said Pedro López, Managing Director at Quintauris, in Paris. “That, combined with the industry’s shift toward greater standardization – finding the right balance between commonality and differentiation – is the perfect mix for success.”

“If we want an industry where we can choose between three, four, or five IP vendors – and avoid vendor lock-in – then standardization is essential”, said López. What’s needed, he said, is a business model that enables IP vendors to keep innovating while remaining financially sustainable – especially given that many programs have 5- to 10-year development cycles. In other sectors, like software, this has led to consolidation, where only a few players can realistically participate.

Collaboration has an important role to play in safety, too, added Ventura. “I’m looking forward to seeing the RISC-V ecosystem deliver something like the AUTOSAR E-GAS [electronic gas pedal] concept, where multiple OEMs come together to build a shared functional safety culture in which suppliers have the same concept, but different implementations.”

5. Safety, Security and Real-Time Performance

RISC-V International CEO Andrea Gallo speaks at the Automobil-Elektronik Kongress (AEK) in Ludwigsburg, in June

“Dependability is a triangle: safety, cybersecurity, and real-time”, said Jyotika Athavale (in red, above – then at Synopsys, now functional safety lead at Waymo), in Ludwigsburg. “The work we are doing in the standards space addresses the need for dependability and interoperability between each of these technologies.”

Each side of that triangle plays a distinct role in ensuring trust in modern automotive systems. Functional safety ensures the system behaves predictably in the face of faults. Cybersecurity protects that behavior from external manipulation. And real-time performance ensures that both happen within the strict timing constraints required for physical systems like braking, steering, or sensor fusion.

Forging this dependability triangle in silicon means taking a system-level view of safety – not just certifying IP blocks in isolation, but recognizing how they behave as part of an integrated compute platform. “It would be great to see a common safety concept for the CPU,” Ventura added. “One developed in collaboration with the ecosystem – not just focused on the hardware alone.” She emphasized that open discussion of implementation challenges and common hazards could help move RISC-V forward – not just as an ISA, but as a platform that is both safe and secure.

A number of RISC-V International members – including SiFive, Codasip, Andes and Nuclei now have automotive IP that meets the ISO 26262 functional safety standard. But, noted Ventura, while ISO 26262 and ISO/SAE 21434 (cybersecurity) are robust standards, they’re not certifications. ISO26262 includes the ASIL (Automotive Safety Integrity Level) certification framework – and while not mandatory, certification is a clear signal. “With more and more RISC-V CPU cores being certified to ASIL-D or ASIL-B, it shows the industry that we’re serious about what we’re doing.”

With automotive compute architectures shifting rapidly from distributed ECUs to centralized and zonal platforms, the opportunity to reimagine safety is real. “There’s a clear transition happening from traditional ECUs to centralized compute, and in that environment, there’s now space for safer RTOS solutions such as FreeRTOS”, added López.

6. Modularity

“Looking at things in terms of core vehicle functions or solving specific problems – where safety, security, real-time and reliability are really important – will drive very specific decisions in the semiconductor design process” said Moran. “This modularity could come at the hardware architecture level, partitioning ECUs or functions on different SoCs, or down to the chip and chiplet level.”

Moran cites AI as an example of a new, and potentially contentious, capability. RISC-V’s open, flexible standard is fueling the development of AI-native chips and securing its place as the foundation of the next trillion-dollar AI revolution. While implementing AI wholesale would be a risky strategy, modularity enables AI to run unconstrained within stringent constraints. “This way, we enable the kind of innovation happening outside of automotive to come in, to be leveraged, but still bring the automotive guardrails around it”, he said.

“Modularity requires capabilities like physical memory protection, I/O protection, or supervisor domain isolation,” agreed Gallo. “These are all technical requirements driving the evolution of the RISC-V architecture through new modular extensions. Depending on whether you’re designing for an ECU or a zonal controller, you then select the specific extensions your product needs.”

Chiplets provide a fundamentally modular solution to this problem. Enabling different computing components (CPU, GPU, IO, safety islands) to be combined into a chip using standard interfaces offers marked benefits, from mixing ISAs (potentially giving carmakers a way to methodically introduce RISC-V into their vehicles) to enabling mixed lifecycles with certain chiplets staying the same while others are refreshed.

“One of the benefits of chiplets is that you get a very clear hardware isolation between chiplets that need to be high-grade – ASIL-D level – and others that don’t”, said Bart Placklé, VP Automotive at IMEC. “For example, your neural network engine likely doesn’t require the full rigor of ASIL-D.”

7. Regional Adaptability

7. Regional Adaptability

The car of tomorrow won’t be built in one place for all markets – it will need to be customized, to some degree, to meet distinct regulatory, safety, environmental and consumer demands of each region. Yet that local customization must be balanced with the efficiency of a consistent, global architecture. This is where modularity and standards both play a key role.

“RVA23 mandates extensions that are the same across all geographies”, said Gallo. “The only area that we are leaving as a regional option is encryption, because this needs to comply with national standards.”

“At the European level, we should be aiming for 80 percent common architecture”, said Placklé. “Right now, every OEM has their own operating system – why do we need six or seven in Europe alone? I fully understand the need for high-level differentiation, and that should absolutely remain. But we also need to look seriously at developing a European platform strategy where 80 percent of the stack can be reused. And honestly, I think we’re still quite far from that.”

As one of the most heavily regulated areas of compute, AI faces huge regional variation in attitudes, laws and applications. Modularity, says Moran, is once again the answer here. An automaker might develop a single, global silicon base using a RISC-V CPU chiplet, but vary the AI components by market.

As well as enabling access might enable region-specific functionality too: China’s variant could use an NPU with localized AI tuned to complex city driving, while the German-market version swaps in a more powerful GPU chiplet capable of lane change assist at 150mph+ on the Autobahn. The unified chip architecture keeps costs down while enabling precise regional adaptation.

The momentum behind RISC-V in automotive is undeniable. Vendors tell us they’re no longer pitching RISC-V – they’re discussing implementation details with OEMs who arrive already convinced. The number one question? How quickly they can move.

“From our perspective, we don’t see an alternative – it’s as simple as that”, said López. “We’ve long foreseen that the industry will need what RISC-V is uniquely positioned to provide. And if we do things right as a community, there shouldn’t be a need for any alternative to RISC-V in automotive.”

“The future of mobility is being built right here, right now – and it will be open”, said Schneid. “With RISC-V we are shaping that future of mobility – together.”

Join us during IAA Mobility 2025

Tuesday, September 9 · 1:30 – 10pm CEST

The conversation continues at the RISC-V Automotive Conference 2025 at Wappenhalle, Munich, adjacent to IAA Mobility 2025. Join us for free and hear directly from the voices leading this transformation.